by Siôn Jones | 14 Jan 2020 | Industry News

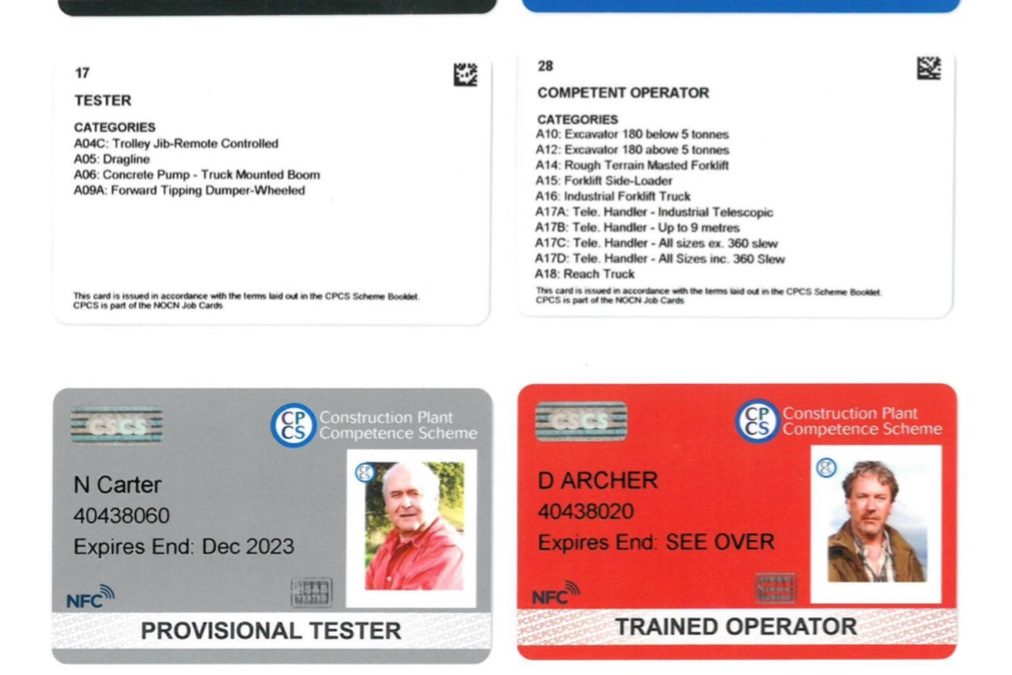

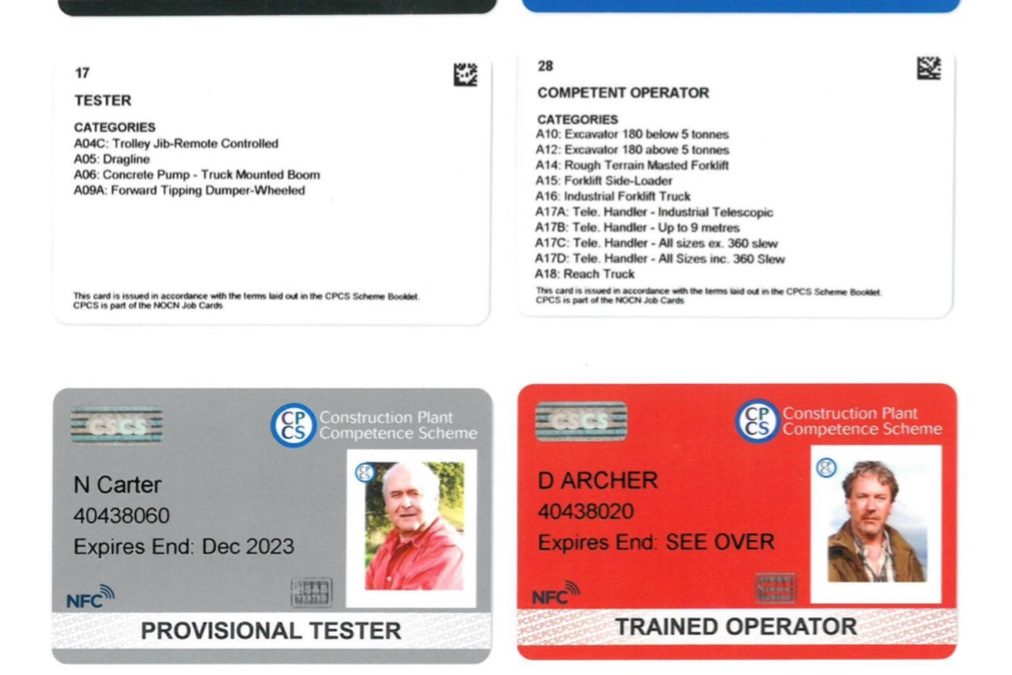

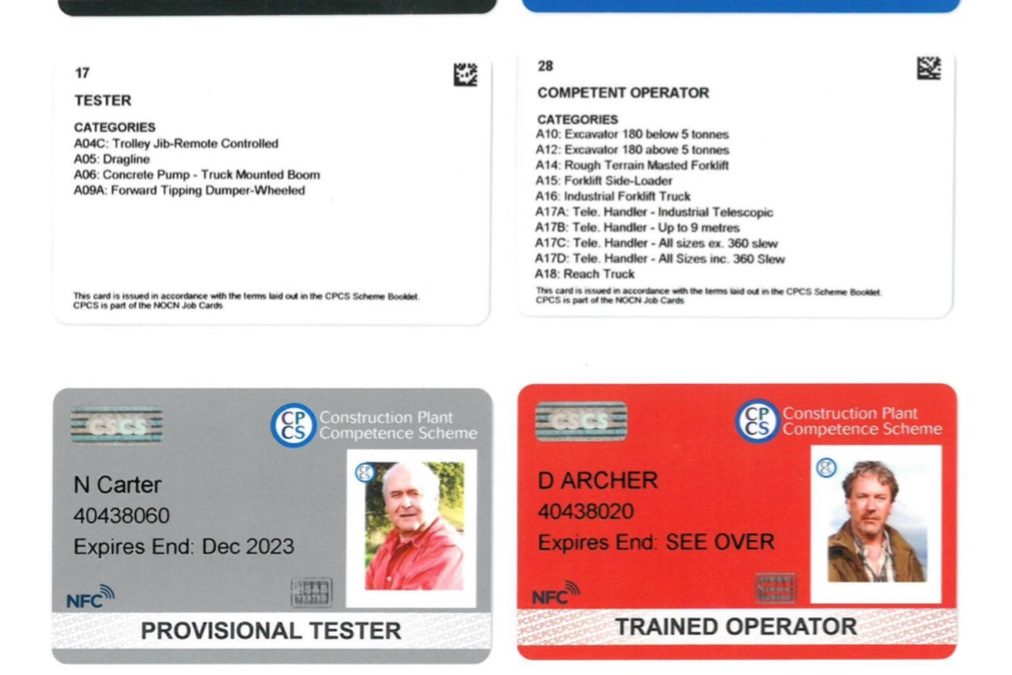

All CPCS operators who apply for a card from 2nd December 2019 will receive a digital card in return. This is because NOCN Jobcards have now launched the much awaited CPCS SMART cards! Here’s a list of some of the changes; New design with block colours to align...

by Siôn Jones | 2 Oct 2019 | General

The sudden removal of the CPCS validator from the scheme in August 2019 came as some surprise to the majority of test centres and companies directly involved within the blue card renewal process. This was compounded by the lack of available information from NOCN...

by Siôn Jones | 12 Aug 2015 | Company News

We have recently purchased a Komatsu dozer, as a result we can now offer CPCS dozer courses at a very competitive rate from our centre in south Wales. If you’d like a quote for training and testing please get in touch. Our courses range from 10 day intensive...

by Siôn Jones | 24 Jul 2015 | General

We have been busy completing NVQs to upgrade appointed person and crane supervisor CPCS tickets all over the UK. If you have a red card for an appointed person, crane (lift) supervisor or slinger/ signaller and need to upgrade to the CPCS blue card, please get in...

by Siôn Jones | 18 Mar 2015

We are running 6 day CPCS Appointed person (A61) course, This involves 5 consecutive days training from Monday to Friday, with CPCS technical test on the following Monday. This course is designed for individuals appointed to plan and manage lifting operations on site....

by Siôn Jones | 18 Mar 2015

We are running 6 day CPCS Appointed person (A61) course, This involves 5 consecutive days training from Monday to Friday, with CPCS technical test on the following Monday. This course is designed for individuals appointed to plan and manage lifting operations on site....

by Siôn Jones | 18 Mar 2015

We are running 6 day CPCS Appointed person (A61) course, This involves 5 consecutive days training from Monday to Friday, with CPCS technical test on the following Monday. This course is designed for individuals appointed to plan and manage lifting operations on site....

by Siôn Jones | 18 Mar 2015

We are running 6 day CPCS Appointed person (A61) course, This involves 5 consecutive days training from Monday to Friday, with CPCS technical test on the following Monday. This course is designed for individuals appointed to plan and manage lifting operations on site....

by Siôn Jones | 18 Mar 2015

We are running 6 day CPCS Appointed person (A61) course, This involves 5 consecutive days training from Monday to Friday, with CPCS technical test on the following Monday. This course is designed for individuals appointed to plan and manage lifting operations on site....

by Siôn Jones | 18 Mar 2015

We are running 6 day CPCS Appointed person (A61) course, This involves 5 consecutive days training from Monday to Friday, with CPCS technical test on the following Monday. This course is designed for individuals appointed to plan and manage lifting operations on site....